Flame Spray Powder Coating System

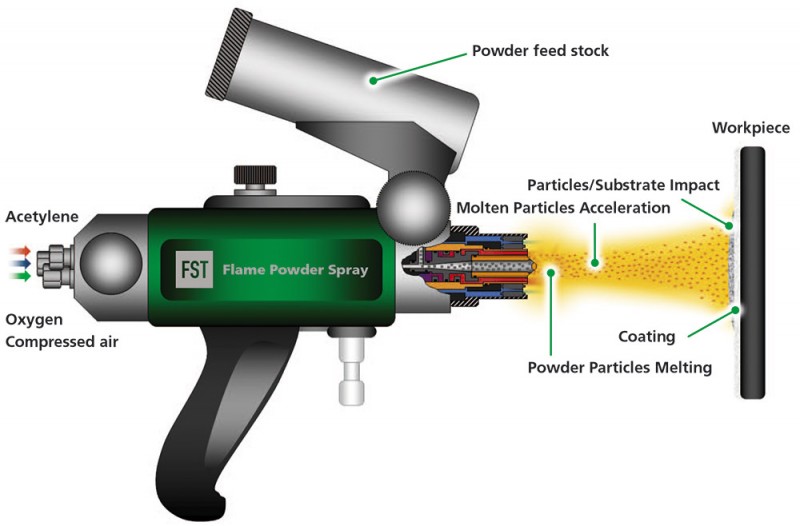

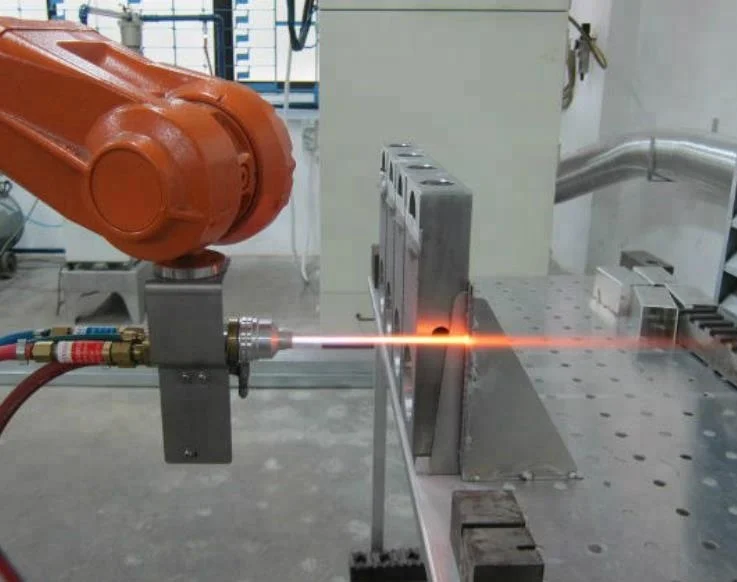

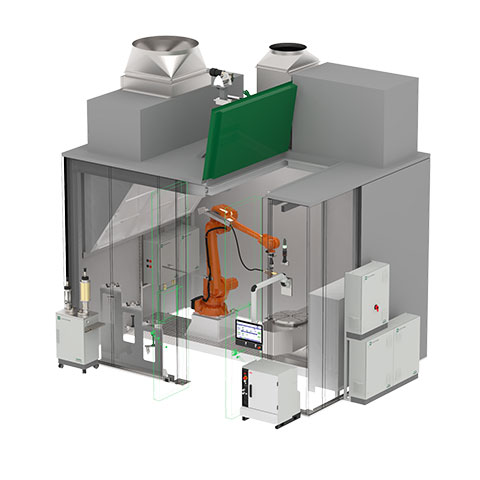

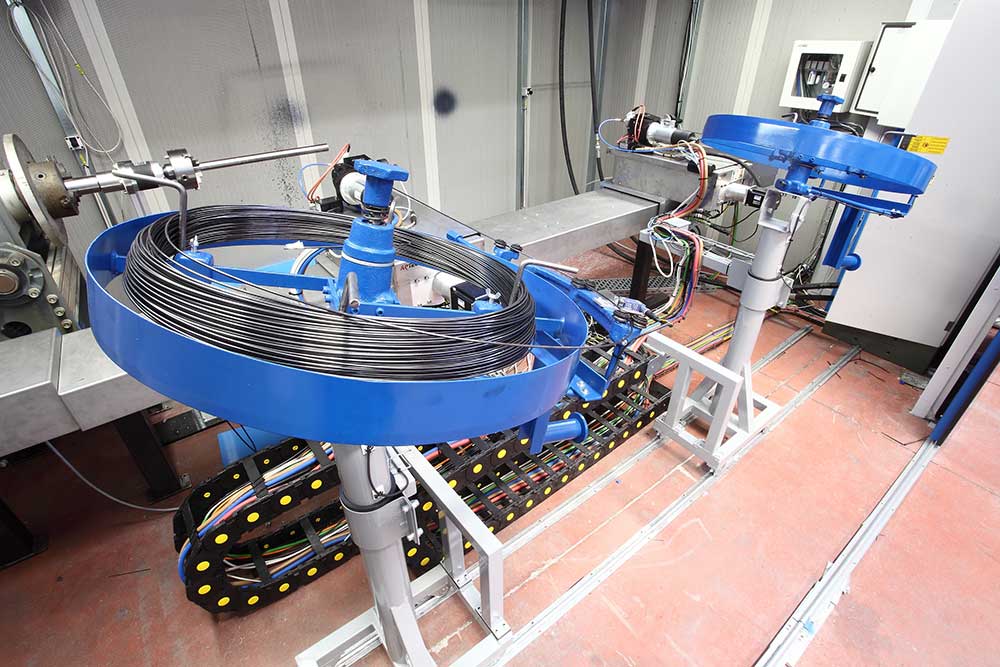

Flame spray powder coating system. The molten material is then atomised with compressed air to create a spray stream that applies the coating onto the surface being sprayed. The Flame or Combustion Powder Spray process uses a similar technique as the Flame Wire Spray process except that the wire feedstock is replaced with a powder. A Powder Feeder is required for 6PM-II Powder Flame Spray System.

The powder flow is started by turning on a switch located on the gun itself or by pressing the gun trigger. Field-applied Flame Sprayed PP PE coatings using selected powder grades eg. 4 rows The RODOJET-9810 system is a perfect combination of the low cost operating flame spray.

Thermal spraying techniques are coating processes in which melted or heated materials are sprayed onto a surface. The coating thickness is dependent on the. The material that melts with this heat source is a powder.

The Hercules flame spray coater is a revolutionary coating system that virtually eliminates all of traditional plaster and paint coating shortcomings. It dries in seconds and is extremely durable therefore the coated structure can be immediately put in service. Anti-corrosion coatings are typically applied with oxy-propane systems.

Spartacus Oil. The powder is fed into the center of the flame where it is melted. It is resistant to chipping peeling and scratching.

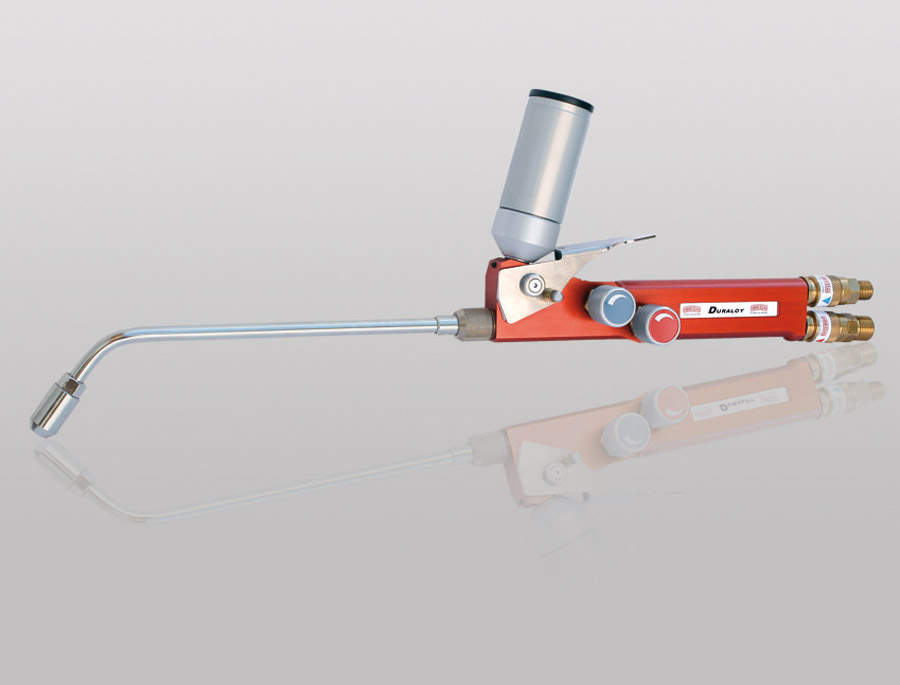

IBIX flame spray coating powder is a thermal Plastic Coating applied pneumatically. Flame spray is a process that uses an oxy-fuel flame to melt wires and in some cases powders or ceramic rods. Spartacus Flame Coating System Special Features IBIX flame spray coating powder is a thermal plastic applied pneumatically.

The flame is then adjusted. A Flame Spray gun uses oxygen and fuel gases to produce a flame into which powder is.

4 rows The RODOJET-9810 system is a perfect combination of the low cost operating flame spray.

It dries in seconds and is extremely durable therefore the coated structure can be immediately put in service. The flame is then adjusted. Flame spray coating involves blowing a plastic powder through a flame that partially melts the powder and fuses it as it contacts the substrate. A Flame Spray gun uses oxygen and fuel gases to produce a flame into which powder is. Flame spray is a process that uses an oxy-fuel flame to melt wires and in some cases powders or ceramic rods. Now the powder is propelled through the gun by dry compressed air and hits the preheated substrate and immediately melts adhering to the substrate. The parts surface is preheated with the flame. The Flame Spray technology is the only system which can apply powders on site and with no need for a coating line. Our 6PM-II provides high spray rates with low gas consumption and high deposit efficiencies can be achieved.

The powder is fed into the center of the flame where it is melted. Spartacus Flame Coating System Special Features IBIX flame spray coating powder is a thermal plastic applied pneumatically. The main advantage of this process is that a much wider range of materials such as nickel or cobalt-based self-fluxing alloys or ceramic materials can be easily processed into. Flame spray coating involves blowing a plastic powder through a flame that partially melts the powder and fuses it as it contacts the substrate. It delivers high performance and versatility in a compact system. It is resistant to chipping peeling and scratching. Spartacus Oil.

Posting Komentar untuk "Flame Spray Powder Coating System"